T: +86-577-86867777

E: info@jhenten.com

E: info@jhenten.com

No.808 Haitong Road, Binhai Development Zone,Wenzhou Economic and Technological Development Zone,Zhejiang,China

Views: 0 Author: Site Editor Publish Time: 2025-06-09 Origin: Site

Have you ever wondered how industries like food processing or pharmaceuticals preserve product quality? Vacuum seal mixing devices play a crucial role in this. By using airtight conditions, they help extend shelf life and maintain freshness. In this post, we’ll explore the key components of vacuum seal mixing devices and their functions. You’ll learn how each part contributes to efficient mixing and high-quality results.

A vacuum seal mixing device combines two essential functions: vacuum sealing and mixing. It creates an airtight environment, helping preserve the quality of products while mixing them effectively.

These devices are used in various industries, including food processing, pharmaceuticals, and chemicals. By removing air, they prevent oxidation, contamination, and spoilage, ensuring longer shelf life and better product integrity.

The purpose of these devices is simple: mix products thoroughly under vacuum conditions. This minimizes exposure to oxygen, which could degrade the product. They also help ensure uniform consistency by mixing at precise speeds and temperatures.

In summary, vacuum sealing and mixing work together to achieve high-quality results. By removing air, the process reduces spoilage risks while ensuring the product is evenly mixed.

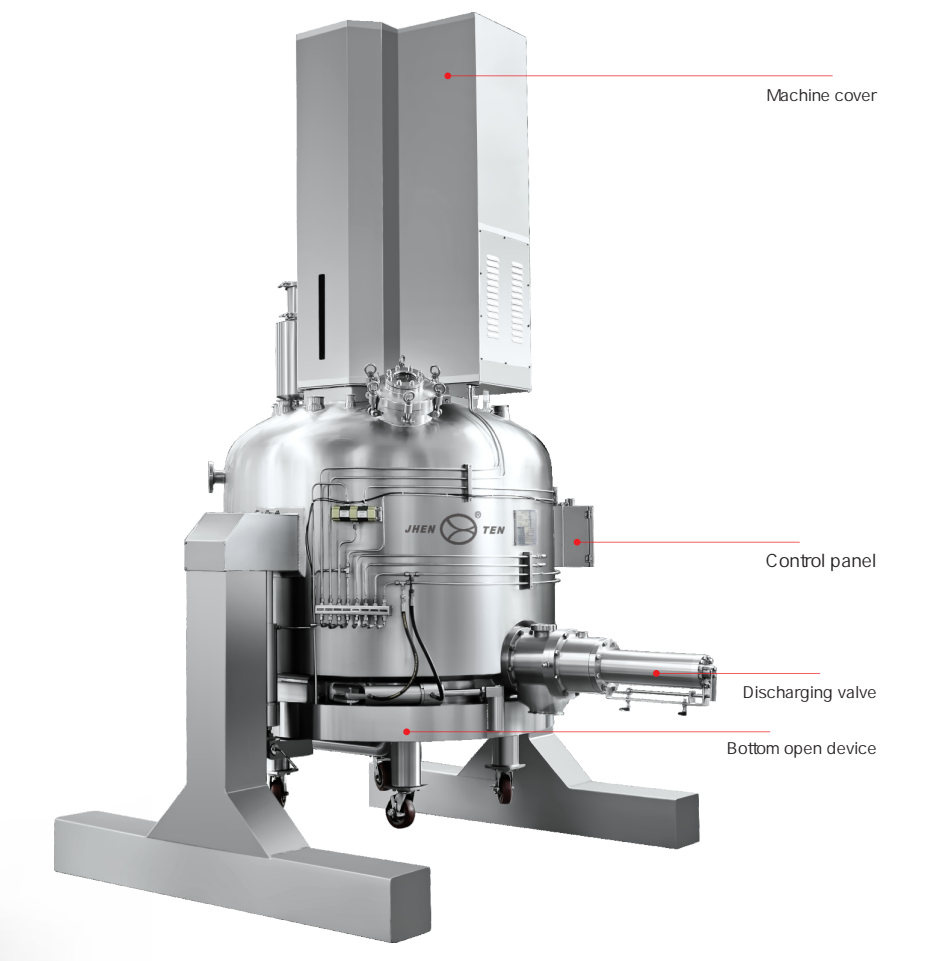

A vacuum seal mixing device is made up of several key components, each playing an important role in maintaining product quality and efficiency.

The vacuum chamber is the heart of the device. It creates an airtight environment by removing air and gases.

This chamber enhances mixing quality by preventing oxidation, contamination, and spoilage. By drawing out air, it ensures products stay fresh and stable throughout the process.

There are different types of mixing mechanisms, including paddle mixing, planetary mixing, and agitators.

Each mechanism impacts mixing efficiency and consistency in unique ways. Paddle mixers are great for gentle mixing, while planetary mixers provide more thorough blending. Agitators help in stirring liquids and semi-solids evenly.

The choice of mechanism depends on the material and desired mixing results.

The vacuum pump is responsible for creating the vacuum. It removes air from the chamber, ensuring an airtight seal.

There are different types of pumps, including oil-lubricated, dry, single-stage, and multi-stage pumps. Each type provides varying levels of vacuum strength and efficiency, depending on the needs of the product.

The control system regulates key factors such as vacuum level, mixing speed, and temperature.

It ensures that everything runs smoothly, allowing for precise control over the process. This is vital for achieving high product quality and maintaining consistency throughout production.

Some vacuum seal mixing devices come with built-in heating and cooling systems. These systems are crucial for temperature-sensitive products.

By controlling temperature during the mixing process, they help prevent product degradation, maintain texture, and preserve nutrients.

Material handling features are essential for maintaining efficiency in the mixing process.

Automation in loading and unloading materials reduces manual labor and speeds up production. This improves overall workflow, especially in high-volume operations.

These components work together to ensure a smooth, efficient, and high-quality mixing process in vacuum seal mixing devices.

Each part of a vacuum seal mixing device plays a vital role, but it's the interaction between them that ensures the system runs smoothly.

The vacuum chamber works by creating a sealed environment. The mixing mechanism then blends the product evenly, while the vacuum pump ensures air is removed, preserving freshness.

The control system continuously monitors and adjusts these processes. It regulates factors like vacuum pressure, mixing speed, and temperature, making sure everything stays in balance.

Heating and cooling systems maintain product stability. If temperature changes are needed, these systems can adjust the environment to preserve texture, flavor, or other sensitive properties.

Each component affects the mixing process in unique ways:

The vacuum environment created by the chamber significantly improves mixing consistency. By removing air, it prevents unwanted reactions and ensures ingredients are evenly combined.

Temperature regulation from the heating and cooling systems directly influences the final product. Maintaining the right temperature ensures that materials are mixed without losing their texture or essential properties.

These interactions and influences are crucial in creating high-quality products in industries that depend on precision, like food processing and pharmaceuticals.

Vacuum seal mixing devices offer several advantages that make them essential in many industries:

Improved Product Quality and Consistency: By mixing in a vacuum environment, these devices ensure uniform blending, leading to more consistent and high-quality products.

Extended Shelf-Life: The airtight seal prevents air and moisture from entering, significantly extending the shelf-life of the product.

Prevention of Oxidation, Air Bubbles, and Contamination: Vacuum sealing reduces the risk of oxidation and air bubbles, keeping products fresh and uncontaminated.

Versatile Applications: These devices are used in various industries, such as food processing, pharmaceuticals, and chemicals, where product integrity is critical.

These advantages make vacuum seal mixing devices a key tool in ensuring the highest standards of product quality and longevity.

Vacuum seal mixing devices are used across various industries where product integrity and quality are critical.

Vacuum sealing helps preserve the flavor, nutrients, and texture of food.

It extends shelf life by preventing oxidation and moisture loss.

Examples include meats, fruits, and dairy products, which remain fresh longer and maintain their taste.

These devices are essential in homogenizing pharmaceutical powders and granules.

They help maintain uniformity and prevent contamination.

Vacuum sealing ensures that active ingredients stay effective and safe throughout the production process.

Vacuum seal mixing devices are ideal for precise formulation and blending of chemical compounds.

They prevent unwanted oxidation and contamination during reactions, ensuring high-quality results.

Vacuum seal mixing devices are also used in labs for controlled sample preparation.

They ensure that sensitive materials are mixed under optimal conditions, which is crucial for accurate experimental results.

These industries benefit from the unique properties of vacuum seal mixing devices, ensuring better product consistency and extended shelf life.

Vacuum seal mixing systems provide several important benefits, especially for industries requiring high-quality products.

Maintaining Product Integrity: Vacuum sealing prevents exposure to air, which helps keep products fresh. This minimizes oxidation, spoilage, and contamination.

Reducing the Need for Preservatives or Additives: Because the vacuum environment preserves freshness, there’s less need for chemicals or preservatives in food and pharmaceutical products.

Lower Energy Consumption: By improving mixing speed and efficiency, these systems can reduce overall energy use. Faster and more efficient processes mean less time and resources are spent on each batch.

Vacuum seal mixing devices are designed to streamline the production process and boost overall efficiency.

Automation and Precise Control: These systems often come with automated features, reducing the need for manual labor. The precise control over factors like mixing speed and temperature ensures consistency and reduces errors.

Increased Production Rates: With minimal downtime and automated processes, production rates can increase significantly. This means more units are produced in less time, without sacrificing quality.

Minimal Product Waste: The efficient design reduces product loss during mixing, ensuring that more of the raw material is used effectively and wasted less.

These benefits make vacuum seal mixing systems a valuable investment for companies looking to enhance efficiency while maintaining high product standards.

Choosing the right vacuum seal mixing device is crucial for ensuring smooth operations and high-quality results. Here are the key factors to keep in mind:

Consider how much material you need to mix at once. Choose a vacuum seal mixing device with the right capacity for your needs. Too small, and you’ll need to do more batches; too large, and you might waste energy and resources.

Different materials (solids, liquids, powders) require different types of mixing mechanisms. Ensure the device you choose can handle the materials you plan to work with. For example, powders may need a different mixing approach compared to liquids.

Automation: Look for devices with automated features that reduce the need for manual labor.

Temperature Control: If you're working with temperature-sensitive materials, opt for systems with precise temperature regulation.

Ease of Cleaning: Consider how easy it is to clean the device. This is especially important for food and pharmaceutical industries.

While it’s tempting to go for the cheapest option, balancing price and performance is key. Higher-priced models may offer better features, but ensure you’re getting the most value for your investment based on your needs.

Always choose a reputable manufacturer, like Multivac or UltraSource. They offer reliable products, good customer support, and warranty options, ensuring you get a device that lasts.

Taking these factors into account will help you select the right vacuum seal mixing device for your business needs.

While vacuum seal mixing devices are highly efficient, they can still face certain challenges. Here are a few common problems:

A vacuum leak can occur if the seal isn’t tight enough. This prevents the device from maintaining an airtight environment, which can affect the mixing process.

Leaks may lead to contamination, spoilage, or uneven mixing, ultimately affecting product quality.

If the device doesn’t create a strong seal, it can cause inconsistent mixing results. This is especially critical in industries like food processing or pharmaceuticals, where uniformity is key.

Mixing performance can be compromised if the vacuum environment isn’t maintained properly.

Temperature control is crucial, especially for sensitive materials. If the device struggles to maintain stable temperature levels, the quality of the product may suffer.

This can cause ingredients to degrade or lose their properties during the mixing process.

To avoid these common problems, here are some solutions:

Keep seals, vacuum pumps, and valves in good condition by checking them regularly. This ensures they work as expected and helps avoid leaks.

If issues arise, troubleshoot by checking for air leaks or damaged parts. Regular maintenance can prevent most problems, but some may require professional repairs.

Clean the device thoroughly after each use to prevent buildup that could interfere with performance. Calibration ensures the device runs efficiently, maintaining optimal mixing and sealing conditions.

Regular maintenance and troubleshooting are key to keeping vacuum seal mixing devices in top shape for long-lasting performance.

Proper maintenance ensures vacuum seal mixing devices run efficiently and last longer. Here are the key maintenance steps:

Regularly clean the vacuum chamber and mixing components to prevent contamination. Buildup from materials can affect the mixing quality and the device's overall performance.

Use non-abrasive cleaners and follow the manufacturer's instructions to avoid damaging sensitive parts.

Lubricating moving parts helps maintain smooth operation. Parts like gears and pumps should be lubricated as needed.

Be sure to use the right type of lubricant, and follow the recommended schedule for application. This prevents wear and tear, ensuring long-term reliability.

Regular calibration of vacuum levels and mixing speed is essential. This ensures the device works at optimal settings, giving you consistent and high-quality results.

Calibration should be done according to the manufacturer's guidelines or when performance seems off.

Cleaning should be done after every use, especially in high-demand environments.

Lubrication and calibration should be performed every few months or as recommended by the manufacturer. This helps avoid minor issues before they become major problems.

It’s a good idea to have the device professionally inspected annually. A technician can identify hidden issues and perform more complex repairs if needed.

By following a routine maintenance schedule, you can extend the lifespan and efficiency of your vacuum seal mixing device.

The future of vacuum seal mixing devices looks promising, with several exciting trends shaping the industry.

The addition of IoT allows for real-time monitoring and data analysis. This enables operators to track performance, adjust settings remotely, and even predict maintenance needs before they arise.

IoT integration ensures that the device is always running at peak performance, improving both efficiency and uptime.

Automation continues to evolve, offering greater efficiency and consistency. These advancements reduce the need for manual intervention, speeding up production cycles while ensuring more accurate results.

As automation improves, systems can now handle more complex tasks, like material handling and precise temperature control, with minimal human involvement.

The industry is also focusing on green technologies. Devices are being designed to use less energy while maintaining high performance.

Energy-efficient models are not only better for the environment but also help businesses reduce operational costs over time.

Features like smart temperature control and remote access are becoming more common. These tools allow operators to adjust settings from anywhere, offering flexibility and greater control.

Advanced temperature regulation ensures that sensitive products are mixed under ideal conditions, preserving their quality and integrity.

These trends will continue to evolve, pushing vacuum seal mixing devices toward smarter, more efficient, and environmentally friendly designs.

Vacuum seal mixing devices are crucial for maintaining product quality across industries. Their key components, like the vacuum chamber and mixing mechanism, ensure consistent and efficient results. Selecting the right device and performing regular maintenance is essential for long-term efficiency and product integrity. With advancements in automation and IoT, these devices will continue to improve.